Important Documents For Admission (2025 - 2026)

Important Documents For Admission (2025 - 2026)

| Degree Awarded | Discipline | Duration | Entry Level | Seats in IIST |

| B.Tech | CM | 4 years | 10+2 (PCM) | 30 |

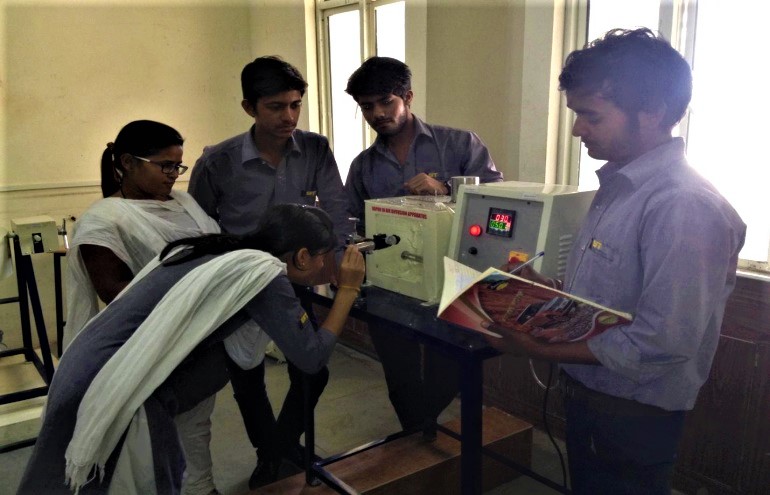

The Department of Chemical Engineering of IIST, Indore is well known for providing a challenging academic program to its students. We also encourage our students to gain real-world engineering experience through industrial visits & projects etc.. Moreover, our graduate course offers exciting and multi-disciplinary opportunities for students to research and explore. Students at IIST get excellent opportunities to work alongside their advisors. IIST has state-of-the-art teaching tools and smart ICT resources. The department also offers specializations in different areas to its undergraduate students as well.

A graduate of the Chemical Engineering Program will demonstrate:

Ability to analyze different physical, chemical and biological systems/processes by applying the knowledge of unit operations and unit processes.

Ability to automate and control processes/systems by designing an environment friendly system for effective reaction, separation and purification and other operations in various processes with proper safety measures using modern engineering tools and simulators

Ability to acquire high end industry centric skills in the field of Chemical Engineering with professional ethics for the benefit of society.

| Univ. Subject Code | Subject Name | CO Description |

| BT-201 | Engineering Physics | The Coursework is designed to provide students the opportunity to learn key concepts of Wave nature of particles and the Schrodinger equation. |

| Student will able to understand the knowledge of Wave optics i.e. interference and diffraction. | ||

| To introduce the idea of solids like semiconductors (P type and N Type semiconductors), Diodes and Hall effect. STudents will also be able to understand the basic concept of superconductivity. | ||

| To develop the understanding of Lasers, fiber optics and their applications in field of engineering sciences. | ||

| To provide you to basic understanding of Electrostatics in vacuum. | ||

| BT-102 | Mathematics-I | To introduce the fallouts of Rolle’s Theorem that is fundamental to application of analysis to Engineering problems. |

| To introduce the idea of applying differential and integral calculus to notions of curvature and to improper integrals. Apart from some applications it gives a basic introduction on Beta and Gamma function | ||

| To develop the tool of power series and Fourier series for learning advanced Engineering Mathematics. | ||

| To familiarize the student with functions of several variables that is essential in most branches of engineering | ||

| To develop the essential tool of matrices and linear algebra in a comprehensive manner. | ||

| BT-203 | Basic Mechanical Engineering | Understand the properties of material, stress strain. Properties of alloys and cast iron. |

| Understand the concept measurement and machine tools their operations and their applications. | ||

| Understand the concept of fluid flow , properties of fluid, Bernoulli’s equation, Pascal’s law. | ||

| To Understand the concept of heat and temperature, law of thermodynamics, boilers and their mountings and accessories, basic Refrigeration cycles and its applications. | ||

| To Understand the working of different cycles and 4 strokes, 2 stroke engines and their applications. | ||

| BT-204 | Basic Civil Engineering & Mechanics | Students will acquire the basic knowledge in different fields of civil engineering and materials used in construction. |

| Gain the ability to use modern survey equipment to measure angles and distances. | ||

| Students will understand the basic of contour lines and map | ||

| Students will have the ability to identify, formulate and solve engineering problems related to Engineering Mechanics: Statics | ||

| Students will be able to analyse beam for shear force and bending moment. | ||

| BT-205 | Basic Computer Engineering | Able to understand the basic applications of computers in various fields, describe operating system, its role and functionalities and to apply concepts of MS word, MS power point, MS Excelefficiently. |

| Discuss and apply simple algorithms for arithmetic and logical problems. | ||

| Translate the algorithms to programs applyingobject-oriented concepts in C++ programming language. | ||

| Understand basics of computer networks, OSI layers and protocols, E commerce applications, impact of securitythreats and attacks on networking systems and also security measures | ||

| Understand the different method for representing and processing data and to get awareness about the impact of cloud computing, its various type of services. | ||

| BT-206 | Language Lab & Seminars | learners to develop good listening skills. |

| Encourages learner to talk freely and lose their shyness when talking in front of the people | ||

| To develop the overall personality of the students by the practical activities | ||

| Helps in confidence building, motivation to be more presentable and help in removing the stage fright | ||

| Develops speaking, writing, reading, listening and presentation skills. | ||

| BT-101 | Engineering Chemistry | Differentiate hard and soft water; solve the related numerical problems on water purification and its significance in industry and daily life. |

| Select the lubricant for various purposes based on the type of Machines. |

||

| Equipped with basic knowledge of polymer , methods of polymerization and various industrial applications of polymers |

||

| Draw the Phase diagrams of one & two component systems and causes, consequences and methods to minimize corrosion to improve industrial designs. | ||

| Identify the structure of unknown/new compounds with the help of spectroscopy and understand periodic properties such as ionization potential, oxidation states and electro negativity | ||

| BT-202 | Mathematics-II | To introduce effective mathematical tools for the solutions of ordinary and partial differential equations that model physical processes. |

| To introduce the tools of differentiation and integration of functions of complex variable those are used in various techniques dealing engineering problems. | ||

| To acquaint the student with mathematical tools available in vector calculus needed various field of science and engineering. | ||

| BT-103 | English for Communication | Effective use of verbal and non-verbal communication for enhanced soft skill beside enhanced reading comprehension as well |

| Write the different kinds of letters, reports and technical writing. | ||

| Apply basic rules of grammar in both written as well as oral communication. | ||

| BT-104 | Basic Electrical & Electronics Engineering | To introduce the concept of Basics of DC electrical Network including network theorems. |

| To introduce the concept of Basics of AC electrical Network(single phase & 3 phase).. | ||

| To study of law of Electromagnetism, introduction of transformer. | ||

| To study of various electrical Machines. | ||

| To study Basic Concept Digital Electronics. | ||

| BT-105 | Engineering Graphics | Draw various types of scales, and curves. |

| Draw orthographic projections of points & lines | ||

| Draw orthographic projections of Planes & Solids | ||

| Draw sections and development of solids including cylinders, cones, prisms and pyramids. | ||

| Draw isometric views of Planes and Solids, Drawing using AUTOCAD. | ||

| BT-106 | Manufacturing Practices | Use hand and power tools for different manufacturing processes |

| Operate machine tools while preparing any component | ||

| Select the appropriate tools required for specific operation. | ||

| Comprehend the safety measures required to be taken while using the tools. | ||

| Prepare Foundry, Fitting, Carpentry, Welding and smithy Job. | ||

| BT-107 | Internship-I (60 Hrs Duration) at the Institute level | Demonstrate the application of knowledge and skill sets acquired from the course and workplace in the assigned job function/s |

| Solve real life challenges in the workplace by analysing work environment and conditions, and selecting appropriate skill sets acquired from the course | ||

| Exhibit critical thinking and problem solving skills by analysing underlying issue/s to challenges | ||

| Demonstrate appreciation and respect for diverse groups of professionals by engaging harmoniously with different company stakeholders | ||

| Exhibit professional ethics by displaying positive disposition during internship | ||

| BT-108 | Swachh Bharat Summer Internship Unnat Bharat Abhiyan (100Hrs)/ Rural Outreach | This course is to sensitize students about the socio-cultural aspects of the rural areas parochial to their colleges. |

| Students are expected to observe, investigate and learn about the following aspects of the rural region: i. Demographics, Literacy, Geographical parameters of the Village; ii. Schemes of government of India and State of Madhya Pradesh in operation in the villages. | ||

| To enhance critical thinking by making them participate in social activities and imbibe human values among them. | ||

| Rural Swachh Bharat Abhiyan is to promote cleanliness and develop healthy habits in people in villages. | ||

| Unnat Bharat Abhiyan: To build an understanding of the development agenda within institutes of Higher Education and an institutional capacity and training relevant to national needs, especially those of rural India. | ||

| BT-301 | Mathematics- III | To determine the root finding techniques which can be used to solve practical engineering problems also demonstrate the use of interpolation methods to find intermediate values in given graphical and/or tabulated data. |

| Apply the concept of numerical analysis to find the relative strengths and weaknesses of each computation method and know which are most applicable for given problem also will be able to approximate and analysis the errors obtained in the numerical solution of equations, ordinary, partial differential equations and simultaneous equations as well. | ||

| To apply the analytical technique to express periodic function as a Fourier series and acquire the concepts of Laplace transformation ; inverse Laplace Transform with its property to solve Partial Differential equation and Ordinary Differential Equation with given boundary conditions which is helpful in all engineering ; research work. | ||

| Apply the concept of a random variable, probability distribution and their application in diversified fields. | ||

| CM-302 | Chemical Engineering Thermodynamics | To understand simple steady and unsteady states, extended with combination of open, closed and isolated systems. |

| To acquire knowledge about PVT behaviour of fluids and using laws to determine process variables. | ||

| To understand Carnot cycle, efficiency of closed loop process and calculation of entropy. | ||

| To apply third law in determining feasibility of reaction and energy correlation with types of reaction/process. | ||

| To calculate output in single and multi-stage process in physical process using fluids.. | ||

| CM-303 | Advance Engineering Chemistry | Ability to familiarize with ceramics and its processing |

| Ability to understand concept of general manufacturing techniques of refractory | ||

| Ability to understand concept of processing of glass and its casting | ||

| Ability to understand the processing of oils and fats. | ||

| Ability to understand the reaction rate mechanism | ||

| CM-304 | Material & Energy Balance | Ability to familiarize with different unit systems and dimensional analysis. |

| Ability to understand concept of ideal gas, real gas, vapor pressure and humidity. | ||

| Ability to solve material balance problems involving recycle, bypass and purge, without chemical reaction. | ||

| Ability to solve material balance problems involving recycle, bypass and purge, with chemical reaction. | ||

| Ability to calculate energy balance using enthalpy changes and solve energy balance involving chemical reactions | ||

| CM-305 | Chemical Instrumentation | 1.Students can understand the use of instrumentations, general characteristics of instruments and types of errors and their remedies. |

| 2. Students able to understand characteristics and working principle of different instruments used to measure temperature and humidity. | ||

| 3. Students able to understand characteristics and working principle of instruments used for pressure measurement and control. | ||

| 4. Students able to analyze different types of flow meters and instruments for the measurement of density and viscosity. | ||

| 5. Students able to design process and instrumentation diagrams (P&ID) for process equipments such as distillation column, heat exchanger and storage tanks. | ||

| CM-306 | Computer Programming-I (JAVA) | Understand and Experiment with Java Database Connectivity (JDBC) |

| Illustrate and Create dynamic web pages, using Servlets and JSP | ||

| Develop reusable Java Bean | ||

| Interpret and Dissect the Remote Method Invocation (RMI) to invoke the remote methods in a variety of applications. | ||

| Demonstrate the multi-tier architecture of Enterprise JavaBeans (EJB) and Struts Framework to Build web-based enterprise applications | ||

| BT-107 | Evaluation of Internship-I completed at I year level | Demonstrate the application of knowledge and skill sets acquired from the course and workplace in the assigned job function/s |

| Solve real life challenges in the workplace by analysing work environment and conditions, and selecting appropriate skill sets acquired from the course | ||

| Exhibit critical thinking and problem solving skills by analysing underlying issue/s to challenges | ||

| Demonstrate appreciation and respect for diverse groups of professionals by engaging harmoniously with different company stakeholders | ||

| Exhibit professional ethics by displaying positive disposition during internship | ||

| BT-307 | 90 hrs Internship based on using various softwares –Internship -II | Exposure to Organizational skills and professional practices. |

| Efficiently completing tasks, fostering good relationship with seniors and subordinates | ||

| Improved Communication & interpersonal skills. | ||

| Exposure to latest technology applications to the specific discipline. | ||

| Identification of relevant problems in the industry and innovative solutions. | ||

| ES-401 | Energy & Environmental Engineering | Get the knowledge of energy carriers, energy technologies, energy challenges and energy system integration and environment sustainability. |

| Learn about the different types of ecosystems present in environment, ecological succession and energy flow in the ecosystem. | ||

| Understand the value of biodiversity to human societies, threats to biodiversity, In-situ and Ex-situ conservation of biodiversity. | ||

| Acquire knowledge of different types of environmental pollution, its effects on life and its remedies | ||

| Aware about the social issue related to the environment, environment ethics, protection and conservation acts for the environment | ||

| CM-402 | Fluid Particle Mechanics | Ability to evaluate size, surface and population of particles, & screen analysis of solids. |

| Ability to understand principle of size reduction, crushing, grinding, pulverizing and ultrafining. | ||

| Ability to design mixing equipment and calculate power requirements. | ||

| Ability to understand principle of separation techniques for system involving solids, liquid sand gases, sedimentation and filtration. | ||

| Ability to understand particulate and aggregative fluidization, pressure drop through fluidized bed. | ||

| CM-403 | Fluid Mechanics | Ability to understand basic concept of fluid static, viscosity, pressure & vapor pressure and dimensional analysis |

| Ability to understand different types of flow, streamlines & continuity equation. | ||

| Ability to understand Euler’s equation of motion, Bernoulli’s equation, linear momentum equation, velocity | ||

| Ability to understand working of pump, fan blowers, compressor and vacuum pumps | ||

| Ability to understand concept of Reynolds number and friction factor | ||

| CM-404 | Inorganic Process Technology | 1. Ability to familiarize process flow diagram of salts and sodium compounds, soda ash, caustic soda. |

| 2. Understand the process flow diagram of hydrochloric acid, sulphur and sulphuric acid, phosphoric acid and phosphate. | ||

| 3. Comprehend the process flow diagram of nitrogenous industries, ammonia and nitric acid, nitrogenous fertilizer. | ||

| 4. Ability to interpret process flow diagram of cement industries and industrial gases. | ||

| 5. Able to understand the process flow diagram of bromine, iodine, Fluorine, soaps and detergents, glass, ceramic and inorganic pigments. | ||

| CM-405 | Fuel Technology | Ability to give the overview of coal Classifications and Washing of coal, mechanism of low and high temperature carbonization. |

| Ability to enhance the knowledge of petroleum processing like cracking, reforming, distillation and isomerization. | ||

| Ability to familiar with properties and testing of petroleum products. | ||

| Ability to know composition and properties of gaseous fuels and fuel cells. | ||

| Ability to understand renewable energy sources. | ||

| CM-406 | Computer Programming-II (Excel) | To perform basic operations using functions/commands of excel. |

| Ability to analyze and solve complex problems | ||

| To solve chemical engineering based problems using excel | ||

| BT-407 | 90 hrs Internship based on using various software’s –Internship -II | Exposure to Organizational skills and professional practices. |

| Efficiently completing tasks, fostering good relationship with seniors and subordinates | ||

| Improved Communication & interpersonal skills. | ||

| Exposure to latest technology applications to the specific discipline. | ||

| Identification of relevant problems in the industry and innovative solutions. | ||

| BT-408 | Cyber Security | Analyze and evaluate the cyber security needs of an organization. |

| Determine and analyze software vulnerabilities and security solutions to reduce the risk of exploitation. | ||

| Measure the performance and troubleshoot cyber security systems. | ||

| Implement cyber security solutions and use of cyber security, information assurance, and cyber/computer forensics software/tools. | ||

| Comprehend and execute risk management processes, risk treatment methods, and key risk and performance indicators | ||

| CM-501 | Mass Transfer-I | To understand the knowledge of mass transfer by applying principles of diffusion, interphase mass transfer and different theories. |

| To understand the concept and operation of various types of gas liquid contact equipment and to determine and analyse mass transfer coefficient. | ||

| Ability to understand the concept of vapour liquid equilibrium, relative volatility and distillation. | ||

| Able to design distillation column. | ||

| To understand the concept and determine NTU , HTU, HETP and height of packed bed used for absorption | ||

| CM-502 | Heat Transfer | Understands the mechanisms of conduction in heat transfer. |

| Understands the mechanisms of convection, overall and individual heat transfer coefficient. | ||

| Understands the mechanisms of radiation. | ||

| Understands the mechanisms of radiation. | ||

| Ability to understand the reaction rate mechanism. CO5 Analyzes the performance of heat exchange equipments. | ||

| CM-503 | Computation Methods in Chemical Engineering | Ability to understand, examine and solve the engineering data by using various methods. |

| Ability to calculate errors occurred in engineering data. | ||

| Ability to solve differential equations for the conservation of mass in chemical engineering problems | ||

| Ability to solve ODE by numerical methods for prediction of data at any instant in chemical engineering problems. | ||

| To solve finite difference, linear & non-linear difference method and optimization in chemical engineering related problems | ||

| CM-504 | A. Organic Process Technology B. Fuel Cell Technology C. Energy Management |

1. Ability to familiarize process flow diagram of pulp and paper manufacturing process. |

| 2. Understand the process flow diagram of sugar and alcohol derivatives like acetic acid, acetic anhydride, vinyl acetate and ethylene glycol. | ||

| 3. Comprehend the process flow diagram of Intermediates for petrochemical like phenol, methanol, propylene, benzene, toluene etc. | ||

| 4. Ability to interpret process flow diagram of dyes, insecticides, pesticides, and nitrating agents. | ||

| 5. Able to understand the process flow diagram of manmade fibers. | ||

| CM-505 | Chemical Process Plant Simulation Lab-I | Understanding uses and initializing Matlab. |

| Ability to perform simple mathematical calculation. | ||

| Ability to solve and analyse advance mathematics based problems. | ||

| CM-506 | Organic Process Technology Lab | 1. Ability to determine the iodine value of the given sample of oil and chloride in a given H2O sample by argentrometric method. |

| 2. Ability to prepare of urea formaldehyde resin and oxalic acid from cane sugar. | ||

| 3. Ability to determine the concentration of sugar by using polarimeter. | ||

| 4. Ability to draw process flow diagrams PFD on AutoCAD P&ID. | ||

| CM-507 | Evaluation of Internship-II | Demonstrate the application of knowledge and skill sets acquired from the course and workplace in the assigned job function/s |

| Solve real life challenges in the workplace by analysing work environment and conditions, and selecting appropriate skill sets acquired from the course | ||

| Exhibit critical thinking and problem solving skills by analysing underlying issue/s to challenges | ||

| Demonstrate appreciation and respect for diverse groups of professionals by engaging harmoniously with different company stakeholders | ||

| Exhibit professional ethics by displaying positive disposition during internship | ||

| CM-508 | Minor Project- I | Identify problem in area of Chemical Engineering which requires further investigation. |

| Identify the methods and materials required for the project work. | ||

| Manage the work with team members. | ||

| Formulate and implement innovative ideas for social and environmental benefits. | ||

| Analyze the results to come out with solutions related to the project work. | ||

| CM-601 | Mass Transfer -II | The concept of Equilibrium in adsorption separation operations should be clear. |

| To study the concept Humidification and Dehumidification operations. | ||

| To introduce the concept of drying and drying equipment’s. | ||

| To study the principal of leaching and crystallization. | ||

| To introduce liquid-liquid extraction. | ||

| CM-602 | Chemical Reaction Engineering | To understand the reaction kinetics and method of analysis. |

| To analyze and design chemical reacting system. | ||

| To understand heterogeneous reacting system and non-ideal reactor analysis. | ||

| To study different catalytic reactor. | ||

| To study different Models and Regime for reacting system. | ||

| CM-603 | A. Process Equipment Design I B. Polymer Technology C. Nano Technology |

To understand the concept of stress and strain analysis and able to design different vessel roof. |

| To design pressers vessel under different different operating conditions. | ||

| To understand the design concept of tall vessel and their supporting structure. | ||

| To design different types of flanges and understand different types of equipment testing methods | ||

| CM-604 | A. Chemical Process Control B. Process Optimization Techniques C. Fertilizer Technology |

To understand the knowledge of controlling processes and controllers. |

| To investigate control and instrumentation of chemical engineering equipment’s | ||

| Ability to solve complex equation using laplace tan formations. | ||

| To understand interacting and noninteracting process and their responses | ||

| To know about stability concept and techniques to solve problems on it.. | ||

| CM-605 | Chemical Process Plant Simulation Lab-II | Student will able to simulate of process in “DWSIM” |

| Student will able to simulate Shortcut Distillation, Rigorous Distillation on DWSIM | ||

| Student will able to simulate double pipe Heat Exchanger in DWSIM | ||

| Student will able to simulate CSTR in DWSIM | ||

| CM-606 | Chemical Process Control Lab | To understand the knowledge of thermocouple and Dead weight Pressure Gauge. |

| To understand Characteristics of Control valve and PID Controller. | ||

| Ability to measurement of liquid level by Air purge method. | ||

| To understand interacting and non-interacting process and their responses. | ||

| CM-607 | Internship-III | Exposure to Organizational skills and professional practices. |

| Efficiently completing tasks, fostering good relationship with seniors and subordinates | ||

| Improved Communication & interpersonal skills. | ||

| Exposure to latest technology applications to the specific discipline. | ||

| Identification of relevant problems in the industry and innovative solutions. | ||

| CM-608 | Minor Project II | Identify problem in area of Chemical Engineering which requires further investigation. |

| Identify the methods and materials required for the project work. | ||

| Manage the work with team members. | ||

| Formulate and implement innovative ideas for social and environmental benefits. | ||

| Analyze the results to come out with solutions related to the project work. | ||

| CM-701 | Process Equipment Design-II | Ability to design different types of heat exchangers like double pipe heat exchanger, shell and tube heat exchanger used in chemical industries and to understand the role of heat transfer coefficient and pressure drop in design |

| Ability to design multiple effect evaporators with boiling point rise and without boiling point rise condition | ||

| Ability to design mass exchange equipment like plate and packed column for distillation and absorption column used in chemical refineries | ||

| Ability to design Flash drum, Kettle reboiler, condenser, cooling tower, rotary drier and tray drier | ||

| CM-702 | A Transport Phenomena B Bio Process Technology C Petroleum Refining Engineering |

Ability to understand origin, composition & classification of petroleum. |

| Ability to understand crude oil distillation process & to understand the concept of catalytic cracking and reforming processes. | ||

| Ability to discuss alkylation, isomerization, polymerization processes. | ||

| Ability to understand the manufacture of lubricating oil & to know sweetening and desulphurization processes. | ||

| Ability to enhance the knowledge of petroleum products, their properties and characterization and discuss about LPG and hydrogen recovery. | ||

| CM-703 | A. Environmental Engineering B. Process Intensification C. Non-conventional energy Sources |

Ability to understand characteristics & effect of pollution on living and non-living things and to know various policies for pollution control. |

| Ability to understand the effect of climate changes, atmospheric dispersion of air pollutants, and operating principles. | ||

| Ability to understand effect of water pollution and working principles of particulate control devices. | ||

| Analyze the hazardous and nonhazardous solid wastes and select the treatment and disposal methods. | ||

| To analyse the pollution caused by different Chemical Process (case studies) | ||

| CM-704 | Energy Lab | 1. Student will able to identify various forms of renewable energy |

| 2. Student will able to understand biogas plant, gasifier and production of Biogas | ||

| 3. Student will able to understand production process of biodiesel, bio-fuels | ||

| 4. Student will able to understand solar drying system, solar distillation and solar Pond | ||

| 5. Student will able to determine of exhaust gas analysis by using Orsat apparatus. | ||

| CM-705 | Environmental Engineering Lab | Student able to determine oxygen demand required to decompose organics in polluted water |

| Student able to determine pH, acidity and alkalinity present in polluted water | ||

| Student able to determine hardness and turbidity of given water sample | ||

| Student able to determine Total Dissolved Solids in water. | ||

| CM-706 | Major Project-I | Identify problem in area of Chemical Engineering which requires further investigation. |

| Identify the methods and materials required for the project work. | ||

| Manage the work with team members. | ||

| Formulate and implement innovative ideas for social and environmental benefits. | ||

| Analyze the results to come out with solutions related to the project work. | ||

| CM-607 | Evaluation of Internship -III | Demonstrate the application of knowledge and skill sets acquired from the course and workplace in the assigned job function/s |

| Solve real life challenges in the workplace by analysing work environment and conditions, and selecting appropriate skill sets acquired from the course | ||

| Exhibit critical thinking and problem solving skills by analysing underlying issue/s to challenges | ||

| Demonstrate appreciation and respect for diverse groups of professionals by engaging harmoniously with different company stakeholders | ||

| Exhibit professional ethics by displaying positive disposition during internship | ||

| CM-801 | Chemical Process Modeling & Simulation |

1. Gaining the knowledge of basics of modeling and simulation. |

| 2. Ability to model the different static and dynamic models. | ||

| 3. Understanding the concept of the treatment of experimental data. | ||

| 4. Understanding of dynamic modeling of simple processes. | ||

| 5. Understanding of computer programming of various iterative convergence methods such as Newton- Raphson, false position etc. | ||

| CM-802 | A. Process Piping Design B. Process safety & Hazards Management C. Fertilizer Technology |

Able to select piping system components. |

| Understand the rheological and time dependent behavior of fluid | ||

| To be able to calculate power losses for Compressible and Incompressible fluids in vertical flow | ||

| To be able to calculate power losses for Compressible and Incompressible fluids in horizontal flow | ||

| Understand the importance of software and piping system in Chemical Industry | ||

| CM-803 | A Process Plant Economics & Management B Petrochemical Technology C IPR (Intellectual Property Right) |

1. To study the concepts of chemical process plant design |

| 2. To understand the economics of plant establishment. | ||

| 3. To understand the cost analysis of products | ||

| 4. To study the process to check the financial feasibility of plant. | ||

| 5. To study the overall network design of process plant. | ||

| CM-804 | Petrochemical Technology Lab | Ability to understand origin, composition & classification of petroleum. |

| Ability to understand crude oil distillation process & to understand the concept of catalytic cracking and reforming processes. | ||

| Ability to discuss alkylation, isomerization, polymerization processes. | ||

| Ability to understand the manufacture of lubricating oil & to know sweetening and desulphurization processes. | ||

| Ability to enhance the knowledge of petroleum products, their properties and characterization and discuss about LPG and hydrogen recovery. | ||

| CM-805 | Major Project-II | Identify the complex engineering problems relevant to the society and industry |

| Apply modern technologies, tools and systems in the field of Chemical Engineering to analyze the identified problem | ||

| Design and implement a viable solution to the problem. | ||

| Apply communication, writing skills & Presentation skills | ||

| Develop the team work and leadership skills with professional and ethical values. |

| Name of SIG | Name of Event under SIG |

| Process & Instrumentation Diagram | Introduction to Process Control and Instrumentation

Internship on “Industrial Analytical Chemical Instrumentation”

Workshop in “Importance of Process & Instrument Diagram (P&ID) in Chemical Industries”

|

| Computational Numerical Statistics | Certification Course on “Application of Data Science for Chemical Engineers through SPSS”

Training on “Unit Operations and Process Calculations on Real/ Live Industrial Projects”

|

| Process Integration & Pinch Technology | Internship on “Process Plant Modeling & Simulation using CHEMCAD”

Workshop on “Application of CHEMCAD Software in Chemical Industries”

Expert Lecture on “Role of Simulation Software in Process Industries”

|

| Industrial Safety Management | Expert lecture on “Chemical Process Plant Safety Software- HAZOP” |

| CHEM-INFINITO 2K23

(Under IIChE Chapter) |

Chem-E-ToK (Quiz Competition)

Post Perfe-Chem (Poster Presentation)

Ace4Chem (Blog Writing Competition)

Sports Activity (Cricket Match)

|

| Name of the S.I.G. | Name of the event under S.I.G. |

| Process integration & Pinch Technology | Training on Importance of Process & Instrumentation Diagrams |

| Computational Numerical Statistics | Internship on Computational Techniques in Process Calculations |

| AI/Machine Learning in Process Industries | Internship on Python for Chemical Engineering Calculations |

| Clean Energy | Certificate Course on Solid and Hazardous Waste Managment |

| Process & Instrumentation Diagram | Internship on Process & Instrumentation Diagrams |

| Name of the S.I.G. | Name of the event under S.I.G. |

| Clean Energy | Workshop on Sustainable energy Technique |

| Process integration & Pinch Technology | Training on Basic to Advance process calculation for chemical engineers |

| Industrial Safety & Management | Expert lecture on Industrial Safety. |

|

Computational Numerical Statistics

|

Training on Numerical Techniques/Statistical Analysis |

| Internship on Computational Techniques in Process Calculations | |

| Internship on Numerical Problem solving with Scilab | |

| Certificate course on Computation Software for Process Calculation | |

| FDP on Process Calculation using Advance Excel |

| Name of the S.I.G. | Name of the event under S.I.G. |

| Waste to wealth | Industrial Visit to Rama Phosphates Limited, Dharampuri, Indore (M.P.) |

| ChemPro Solution | Workshop on Next Generation Engineering or Emerging Technology |

| Renewable Energy | Training on Unit Operations and Process Calculations on Real/ Live Industrial Projects |

| Name of the S.I.G. | Name of the event under S.I.G. |

|

ChemPro Solution

|

FDP on Solving & Optimization of Chemical Engineering Problems using Scilab |

| Internship on Process & Instrumentation Diagrams in Refineries | |

| Workshop on Line Sizing & Pressure drop Calculation Using AFT Fathon | |

| Waste to Wealth | Expert Lecture on Removal Of Scaling from Cooling Tower and Evaparators by Scaleban Equipment |

| Renewable Energy | Training on Proces safety & Risk Management |

Chemical Engineers are responsible for developing new industrial processes and designing new process plants and equipment or modifying existing ones. The role of chemical engineers is to design and troubleshoot the production processes through process automation, waste and energy management. They are often employed by large scale manufacturing plants to increase productivity and product quality while reducing costs. Along with the production industries and technical advancements, demand of skill graduate engineers is also increasing. In the view of this demand, our department has constituted 7 SIG’s for the students. In which they will get the

opportunity to upgrade their skills according to their interest.

1) SIG- Computational Analysis Techniques

Students are trained in high level critical and creative thinking skills. With the help of SPSS and EXCEL software they can solve chemical industries numerical problems with the ease.

2) SIG- Process & Instrumentation Design

Students will learn about the operations of various instruments used in the chemical industries, how to read and draft piping and instrumentation diagrams which is the very crucial step in any process industry. With the help of AutoCAD P&ID software and EXCEL students will able to do piping design like line sizing for liquid, gas and fluid mixtures.

3) SIG- Clean Energy

Through this SIG students will get knowledge about renewable energy technologies like Fuel Cell, Solar cells, Bio Energy etc., Live models will be prepared for domestic and Industrial purpose.

4) SIG- Process Integration with Pinch Technology

Students will learn about the “Systematic and general methods for designing integrated production systems, ranging from individual processes to total sites with special emphasis on the efficient use of energy and reducing environmental effects”. The main aim of this SIG is to teach students how to reduce the operating cost of existing plants, while new processes often can be designed with reduction in both investment cost and operating cost. Hands on training on MATLAB, CHEMCAD, ASPEN EDR-HTRI, ASPEN HYSIS, AFT Fathom, DWSIM software.

5) SIG- Industrial safety Management

This SIG aims in designing and operation of safe and cost-effective processes. Student will be educated about personal protective equipment, fire safety, hazardous materials and their symbols. Students will gain insights to recognize the importance of a safe work environment with live Industrial training.

6) SIG- AI/Machine Learning in Process Industries:

Students will able to adopt Machine Learning / AI techniques in chemical industries, like statistical machine learning, evolutionary computation in petroleum product characterization, chemical change modeling and process optimization, decision-making, environmental perception, and digital troubleshooting of varied problems within the industry. Coding skills will be given by PYTHON software

7) SIG- Nano Technology for waste management

Under this SIG student will able to learn state of the art techniques used in waste management like Nanotechnology and using smart polymers. Skills will be developed in synthesis and characterization techniques like XRD, FT-IR, SEM , UV Spectroscopy, HPLC, Gas Chromatography.

Industries

Research areas

Department of Chemical Engineering

List of publications of faculty

| S. No. | Name of Faculty | Title Name | Name of Journal | Publication Date |

| 1. | Mrs. Samatha Singh | A review on various MFC for power generation | Journal of Biofuel and Bioenergy | June 2016 |

| 2. | Mrs. Samatha Singh | Production of biodegradable plastic (polylactic acid) from mollasses | International journal of engineering science and humanities | 2012 |

| 3 | Mrs. Samatha Singh | A review on MFC using organic waste as feed | CIB Tech Journal of biotechnology | 2012 |

| 4 | Mrs. Samatha Singh | Advance oxidation process for waste water treatment: A Review | International Journal of Innovative Research in Science,Engineering and Technology | January 2019 |

| 5 | Mrs. Samatha Singh | Production of an Organic fertilizer from Garden waste | Journal of Emerging Technologies and Innovative Research | May 2019 |

| 6 | Mr. Rahul Gupta | Review on Reactive Distillation and Recent Applications

|

Imperial Journal of Interdisciplinary Research | November 2016 |

| 7 | Mr. Rahul Gupta | “Hydraulic Speed Breaker Power Generator” | International Journal of Engineering Research & Applications, Volume 3, Issue 6. | November- December 2013 |

| 8 | Mr. Rahul Gupta | Production of an Organic fertilizer from Garden waste | Journal of Emerging Technologies and Innovative Research | May 2019 |

| 9 | Rahul Bhargava | Techniques Available for the Extraction of Essential Oils from Plants: A Review | International Journal for Research in Applied Science &Engineering Technology(UGC Approved) | March-2018 |

| 10 | Rahul Bhargava | Production of Ethanol from Corn using Yeast

( Saccharomyces Cerevisiae) |

International Journal of Innovative Research in Science,Engineering and Technology, Volume 5, Issue 12. | December 2016 |

| 11 | Rahul Bhargava |

“Production of Biofuel (Ethanol) from Corn and co product evolution”: A Review |

International Research Journal of Engineering and Technology (IRJET) Volume 3, Issue 12. | December 2016 |

| 12 | Rahul Bhargava | A review on :Electro Coagulation technique on Dairy Waste water Treatment | Imperial Journal of Interdisciplinary Research | November-2016 |

| 13 | Rahul Bhargava |

A Review On: Comparison between Different Techniques for Treating Wastewater |

Imperial Journal of Interdisciplinary Research | November-2016 |

| 14 | Mr. Rahul Bhargava | Advance oxidation process for waste water treatment: A Review | International Journal of Innovative Research in Science,Engineering and Technology, | January 2019 |

| 15 | Mr. Rahul Bhargava | A compressive study on solid and Hazardous waste Management | International Journal of Innovations In Engineering Research & Technology | March 2019 |

| 16 | Mr. Rahul Bhargava | Recent methods available for rerefining of lubricating oil: A review | International Journal for Research in Applied Science &Engineering Technology | April 2019 |

| 17 | Pankaj Malviya |

Evaluation of water quality of Narmada river with reference to physico-chemical parameters |

International journal of engineering sciences & research technology |

2015 |

| 18 | Pankaj Malviya | Physico- chemical parameters of Narmada RiverWater: A review | International Journal of Chemical Studies | 2015 |

| 19 | Pankaj Malviya | Production of bio-plastic from food waste | IRJET | Under Process |

| 20 | Pankaj Kumar | Advance oxidation process for waste water treatment: A Review | International Journal of Innovative Research in Science,Engineering and Technology, | January 2019 |

| 21 | Pankaj Kumar | A compressive study on solid and Hazardous waste Management | International Journal of Innovations In Engineering Research & Technology | May 2019 |

| 22 | Farhin Khan | A Review On Technicques Available For The Extraction of Essential Oils From Various Plants | International Research Journal of Engineering &Technology | May 2018 |

| 23 | Farhin Khan | Study of Essential oil extraction from Eucalyptus and Lemon grass using hydro distillation method. | International Research Journal of Engineering & Technology | March 2019 |

| 24 | Mrs. Samatha Singh | Design of Sewage Treatment Plant for Small Town | International Journal for Research in Applied Science & Engineering Technology |

May 2020 |

| 25 | Mrs. Samatha Singh | Graphene as electrode material for the greater power generation in microbial fuel cell | International Journal of Chemical & Petrochemical Technology (Scopus) |

2019 |

| 26 | Mrs. Samatha Singh | Microbial fuel cell: a novel technology for energy generation and comparison of power densities for different electrodes using nano technology | Elsevier | 2019 |

| 27 | Mr. Rahul Gupta | Design of Sewage Treatment Plant for Small Town | International Journal for Research in Applied Science & Engineering Technology |

May 2020 |

| INDUSTRIAL TOUR | |||

| S. No. | Industry Name/ Research Centre | Date | Type of Company |

| 1 | Rama Phosphate Ltd. Dharampuri, Indore | 4th Oct. 2019 | Private Limited |

| 2 | Hindustan Petroleum Corporation Ltd. Magliya | 9 Feb.2019 | Government |

| 3 | Jalud Water Treatment Plant Visit | 29-Apr-17 | Government |

| 4 | Raja Ramanna Centre for Advanced Technology (RRCAT), Indore | 27 Jan. 2017 | Research centre |

| 5 | Symbiotic Pharma Pvt. Ltd. Indore | 22 Oct., 2016 | Private Limited |

| 6 | Sanchi Dugdh Sangh, Mangliya, Indore | 12-Mar-16 | Public Limited |

| 7 | Wind Mills, Dewas | 6 Nov., 2015 | Government |

| 8 | Tata International Ltd., Dewas (M.P) | 12-Mar-15 | Exporter / Manufacturer / Supplier |

| INDUSTRIAL TOUR | |||

| S. No. | Industry Name | Date | Type of Company |

| 1 | K.C Engineers | 27th – 3rd April,2016 | Pivate Ltd. |

| 2 | Nuclear Power Corporation Of India Limited, Tarapur | 9th – 15th March ,2017 | Government |

| 3 | Hindustan Petroleum Corporation Limited (HPCL), Vishakapatnam , Vizag steel museum , submarine museum | 3rd – 9th March ,2018 | Government |

| 4 | Vardhman Textile Ltd. Baddi, Himachal Pradesh | 3rd – 10th January 2019 | Pivate Ltd. |

1. ISTE Students Chapter:

Providing quality training programmes to teachers and administrators of technical institutions to update their knowledge and skills in their fields of activity. To assist and contribute in the production and development of top quality professional engineers and technicians needed by the industry and other organizations. Providing guidance and training to students to develop better learning skills and personality.

Providing quality training programmes to teachers and administrators of technical institutions to update their knowledge and skills in their fields of activity. To assist and contribute in the production and development of top quality professional engineers and technicians needed by the industry and other organizations. Providing guidance and training to students to develop better learning skills and personality.

2. Swayam Students Chapter:

SWAYAM is an initiative by Ministry of Human Resource Development, Government of India. World’s largest SWAYAM MOOCs (Massive Open Online Courses), a new paradigm of education for anyone, anywhere, anytime, as per your convenience, aimed to provide digital education free of cost and to facilitate hosting of all the interactive courses prepared by the best more than 1000 specially chosen faculty and teachers in the country. SWAYAM MOOCs enhances active learning for improving lifelong learning skills by providing easy access to global resources.

SWAYAM is an initiative by Ministry of Human Resource Development, Government of India. World’s largest SWAYAM MOOCs (Massive Open Online Courses), a new paradigm of education for anyone, anywhere, anytime, as per your convenience, aimed to provide digital education free of cost and to facilitate hosting of all the interactive courses prepared by the best more than 1000 specially chosen faculty and teachers in the country. SWAYAM MOOCs enhances active learning for improving lifelong learning skills by providing easy access to global resources.

3. Indian Institute of Chemical Engineers:

Department of Chemical Engineering is proud to be associated with Indian Institute of Chemical Engineers (IIChE) as an organizational member. The IIChE publishes a quarterly journal, the Indian Chemical Engineer (ICE) and conducts annual session known as the Indian Chemical Engineering Congress (CHEMCON).