Important Documents For Admission (2025 - 2026)

Important Documents For Admission (2025 - 2026)

| Degree Awarded | Discipline | Duration | Entry Level | Seats in IIST |

| B.Tech | Mechanical Engineering | 4 years | 10+2 (PCM) | 30 |

The department of Mechanical Engineering is established in the year 2003, Presently has a seat intake of 30 in B.Tech programe. Bachelor of Technology in Mechanical Stream is affiliated to “ Rajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal “and Approved by All India Council for Technical Education (AICTE). The Department of Mechanical Engineering is continuously striving to achieve excellence in education, academics and industry oriented research as well as consultancy work with service to the society.

Mechanical Engineering is a very strategic and specialized segment, where the engineers are trained to meet the innovative demands of futuristic technologies. The Department of Mechanical Engineering at IIST is established as one of the premier brands in technical education in the region. Major highlights of the mechanical engineering department are as follow:

Students have an excellent track record of achievement in various sports Competitions (Nodal, State and National Level) held at various prestigious institutions of India

PSO1: Apply the fundamentals of mathematics, science and engineering knowledge to identify, formulate, design, investigate and solve complex engineering problems of machines & mechanisms, kinematics and dynamics, mechanical components & systems to manufacturing facilities having computer-based design, analysis, simulation and fabrication with best quality practices.

PSO2: Design mechanical systems in various fields such as machine elements, thermal, manufacturing, industrial and inter-disciplinary fields by using various engineering/technological tools to meet the mercurial needs of the industry and society at large.

PSO3: The ability to grasp the latest development, methodologies of mechanical engineering and possess competent knowledge of design process, practical proficiency, skills and knowledge of programme and developing ideas towards innovation & research.

Upon successful completion of the program, the students would have the following attributes.

| Mechanical Engineering (2022-23) | ||

| Univ. Subject Code | Subject Name | CO Description |

| BT-201 | Engineering Physics | The Coursework is designed to provide students the opportunity to learn key concepts of Wave nature of particles and the Schrodinger equation. |

| Student will able to understand the knowledge of Wave optics i.e. interference and diffraction. | ||

| To introduce the idea of solids like semiconductors (P type and N Type semiconductors), Diodes and Hall effect. STudents will also be able to understand the basic concept of superconductivity. | ||

| To develop the understanding of Lasers, fiber optics and their applications in field of engineering sciences. | ||

| To provide you to basic understanding of Electrostatics in vacuum. | ||

| BT-102 | Mathematics-I | To introduce the fallouts of Rolle’s Theorem that is fundamental to application of analysis to Engineering problems. |

| To introduce the idea of applying differential and integral calculus to notions of curvature and to improper integrals. Apart from some applications it gives a basic introduction on Beta and Gamma function | ||

| To develop the tool of power series and Fourier series for learning advanced Engineering Mathematics. | ||

| To familiarize the student with functions of several variables that is essential in most branches of engineering | ||

| To develop the essential tool of matrices and linear algebra in a comprehensive manner. | ||

| BT-203 | Basic Mechanical Engineering | Understand the properties of material, stress strain. Properties of alloys and cast iron. |

| Understand the concept measurement and machine tools their operations and their applications. | ||

| Understand the concept of fluid flow , properties of fluid, Bernoulli’s equation, Pascal’s law. | ||

| To Understand the concept of heat and temperature, law of thermodynamics, boilers and their mountings and accessories, basic Refrigeration cycles and its applications. | ||

| To Understand the working of different cycles and 4 strokes, 2 stroke engines and their applications. | ||

| BT-204 | Basic Civil Engineering & Mechanics | Students will acquire the basic knowledge in different fields of civil engineering and materials used in construction. |

| Gain the ability to use modern survey equipment to measure angles and distances. | ||

| Students will understand the basic of contour lines and map | ||

| Students will have the ability to identify, formulate and solve engineering problems related to Engineering Mechanics: Statics | ||

| Students will be able to analyse beam for shear force and bending moment. | ||

| BT-205 | Basic Computer Engineering | Able to understand the basic applications of computers in various fields, describe operating system, its role and functionalities and to apply concepts of MS word, MS power point, MS Excelefficiently. |

| Discuss and apply simple algorithms for arithmetic and logical problems. | ||

| Translate the algorithms to programs applyingobject-oriented concepts in C++ programming language. | ||

| Understand basics of computer networks, OSI layers and protocols, E commerce applications, impact of securitythreats and attacks on networking systems and also security measures | ||

| Understand the different method for representing and processing data and to get awareness about the impact of cloud computing, its various type of services. | ||

| BT-206 | Language Lab & Seminars | learners to develop good listening skills. |

| Encourages learner to talk freely and lose their shyness when talking in front of the people | ||

| To develop the overall personality of the students by the practical activities | ||

| Helps in confidence building, motivation to be more presentable and help in removing the stage fright | ||

| Develops speaking, writing, reading, listening and presentation skills. | ||

| BT-101 | Engineering Chemistry | Differentiate hard and soft water; solve the related numerical problems on water purification and its significance in industry and daily life. |

| Select the lubricant for various purposes based on the type of Machines. |

||

| Equipped with basic knowledge of polymer , methods of polymerization and various industrial applications of polymers |

||

| Draw the Phase diagrams of one & two component systems and causes, consequences and methods to minimize corrosion to improve industrial designs. | ||

| Identify the structure of unknown/new compounds with the help of spectroscopy and understand periodic properties such as ionization potential, oxidation states and electro negativity | ||

| BT-202 | Mathematics-II | To introduce effective mathematical tools for the solutions of ordinary and partial differential equations that model physical processes. |

| To introduce the tools of differentiation and integration of functions of complex variable those are used in various techniques dealing engineering problems. | ||

| To acquaint the student with mathematical tools available in vector calculus needed various field of science and engineering. | ||

| BT-103 | English for Communication | Effective use of verbal and non-verbal communication for enhanced soft skill beside enhanced reading comprehension as well |

| Write the different kinds of letters, reports and technical writing. | ||

| Apply basic rules of grammar in both written as well as oral communication. | ||

| BT-104 | Basic Electrical & Electronics Engineering | To introduce the concept of Basics of DC electrical Network including network theorems. |

| To introduce the concept of Basics of AC electrical Network(single phase & 3 phase).. | ||

| To study of law of Electromagnetism, introduction of transformer. | ||

| To study of various electrical Machines. | ||

| To study Basic Concept Digital Electronics. | ||

| BT-105 | Engineering Graphics | Draw various types of scales, and curves. |

| Draw orthographic projections of points & lines | ||

| Draw orthographic projections of Planes & Solids | ||

| Draw sections and development of solids including cylinders, cones, prisms and pyramids. | ||

| Draw isometric views of Planes and Solids, Drawing using AUTOCAD. | ||

| BT-106 | Manufacturing Practices | Use hand and power tools for different manufacturing processes |

| Operate machine tools while preparing any component | ||

| Select the appropriate tools required for specific operation. | ||

| Comprehend the safety measures required to be taken while using the tools. | ||

| Prepare Foundry, Fitting, Carpentry, Welding and smithy Job. | ||

| BT-107 | Internship-I (60 Hrs Duration) at the Institute level | Demonstrate the application of knowledge and skill sets acquired from the course and workplace in the assigned job function/s |

| Solve real life challenges in the workplace by analysing work environment and conditions, and selecting appropriate skill sets acquired from the course | ||

| Exhibit critical thinking and problem solving skills by analysing underlying issue/s to challenges | ||

| Demonstrate appreciation and respect for diverse groups of professionals by engaging harmoniously with different company stakeholders | ||

| Exhibit professional ethics by displaying positive disposition during internship | ||

| BT-108 | Swachh Bharat Summer Internship Unnat Bharat Abhiyan (100Hrs)/ Rural Outreach | This course is to sensitize students about the socio-cultural aspects of the rural areas parochial to their colleges. |

| Students are expected to observe, investigate and learn about the following aspects of the rural region: i. Demographics, Literacy, Geographical parameters of the Village; ii. Schemes of government of India and State of Madhya Pradesh in operation in the villages. | ||

| To enhance critical thinking by making them participate in social activities and imbibe human values among them. | ||

| Rural Swachh Bharat Abhiyan is to promote cleanliness and develop healthy habits in people in villages. | ||

| Unnat Bharat Abhiyan: To build an understanding of the development agenda within institutes of Higher Education and an institutional capacity and training relevant to national needs, especially those of rural India. | ||

| BT 301 | Mathematics-III | To determine the root finding techniques which can be used to solve practical engineering problems also demonstrate the use of interpolation methods to find intermediate values in given graphical and/or tabulated data. |

| Apply the concept of numerical analysis to find the relative strengths and weaknesses of each computation method and know which are most applicable for given problem also will be able to approximate and analysis the errors obtained in the numerical solution of equations, ordinary, partial differential equations and simultaneous equations as well. | ||

| To apply the analytical technique to express periodic function as a Fourier series and acquire the concepts of Laplace transformation & inverse Laplace Transform with its property | ||

| To solve Partial Differential equation and Ordinary Differential Equation with given boundary conditions which is helpful in all engineering & research work. | ||

| Apply the concept of a random variable, probability distribution and their application in diversified fields. | ||

| ME302 | Thermodynamics | Apply conservation principles (mass and energy) to evaluate the performance of simple engineering systems and cycles |

| Evaluate thermodynamic properties of simple homogeneous substances | ||

| Analyze processes and cycles using the second law of thermodynamics to determine maximum efficiency and performance | ||

| Discuss the physical relevance of the numerical values for the solutions to specific engineering problems | ||

| Critically evaluate the validity of the numerical solutions for specific engineering problems | ||

| ME303 | Materials Technology | Understand the crystal structure and classification of materials. |

| Understand methods of determining mechanical properties and their suitability for applications. | ||

| Understand Mechanical behavior of metals and alloys, Tensile & compressive stress-strain | ||

| Understand Iron carbon diagram, time temperature transformation etc. | ||

| Understand Non destructive testing, alloty study with heat treatment process. | ||

| ME304 | Strength of Material | To define direct normal stress and direct shear stress and compute their values. |

| able to calculate shear stress distribution in solid and hollow round members under Torsional loading conditions. | ||

| Able to calculate bending stress and shear stress at any location along the beam. Calculate maximum bending stress and maximum shear stress. | ||

| Able to use different theories of failure in different loading condition | ||

| able to develop an understanding of analytic methods used in connection with the structural design of columns, long mechanical members under compression. | ||

| ME305 | Manufacturing Process | Students will be able to understand concepts of casting Technology. |

| Students will be able to understand mechanical working of metals. | ||

| Students will be able to understand concepts of welding process | ||

| Students will be able to understand concept of forging methods | ||

| Students will be able to understand press working . | ||

| ME306 | Thermal Engg Lab | To study the working of different types of high pressure boilers. |

| To calculate different performance parameters of boilers. | ||

| To determine volumetric and isothermal efficiencies of a reciprocating air compressor. | ||

| To study the working of different types of steam condensors. | ||

| To analyse the exhaust gas using ORSAT apparatus. | ||

| BT107 | Evaluation of Internship-I Completed at First Year Level | Demonstrate the application of knowledge and skill sets acquired from the course and workplace in the assigned job function/s |

| Solve real life challenges in the workplace by analysing work environment and conditions, and selecting appropriate skill sets acquired from the course | ||

| Exhibit critical thinking and problem solving skills by analysing underlying issue/s to challenges | ||

| Demonstrate appreciation and respect for diverse groups of professionals by engaging harmoniously with different company stakeholders | ||

| Exhibit professional ethics by displaying positive disposition during internship | ||

| ES401 | ENERGY & ENVIRONMENTAL ENGINEERING | To learn about various types of energy resources. |

| To learn about Ecosystem. | ||

| To learn about Biodiversity and its conservation. | ||

| To learn about Causes, Effects and Control of Environmental Pollution. | ||

| To learn about various social issues w.r.t. environment. | ||

| ME402 | INSTRUMENTATION & CONTROL | To learn about different types of Instrument Systems & Measurement Techniques. |

| To know about various characteristics of measuring instrument. | ||

| To learn about measurement of different physical quantities like Temperature, Flow, Velocity & Pressure | ||

| To learn about different mechanical measurement devices. | ||

| To know about different types of control systems. | ||

| ME403 | THEORY OF MACHINES | To introduce the approaches used in kinematic and dynamic analysis of machinery. |

| To understand the various four bar mechanisms and applications. | ||

| To understand various types of gear and gear trains. | ||

| To understand Cam & folloers working. | ||

| To give basic knowledge on mechanical vibrations. | ||

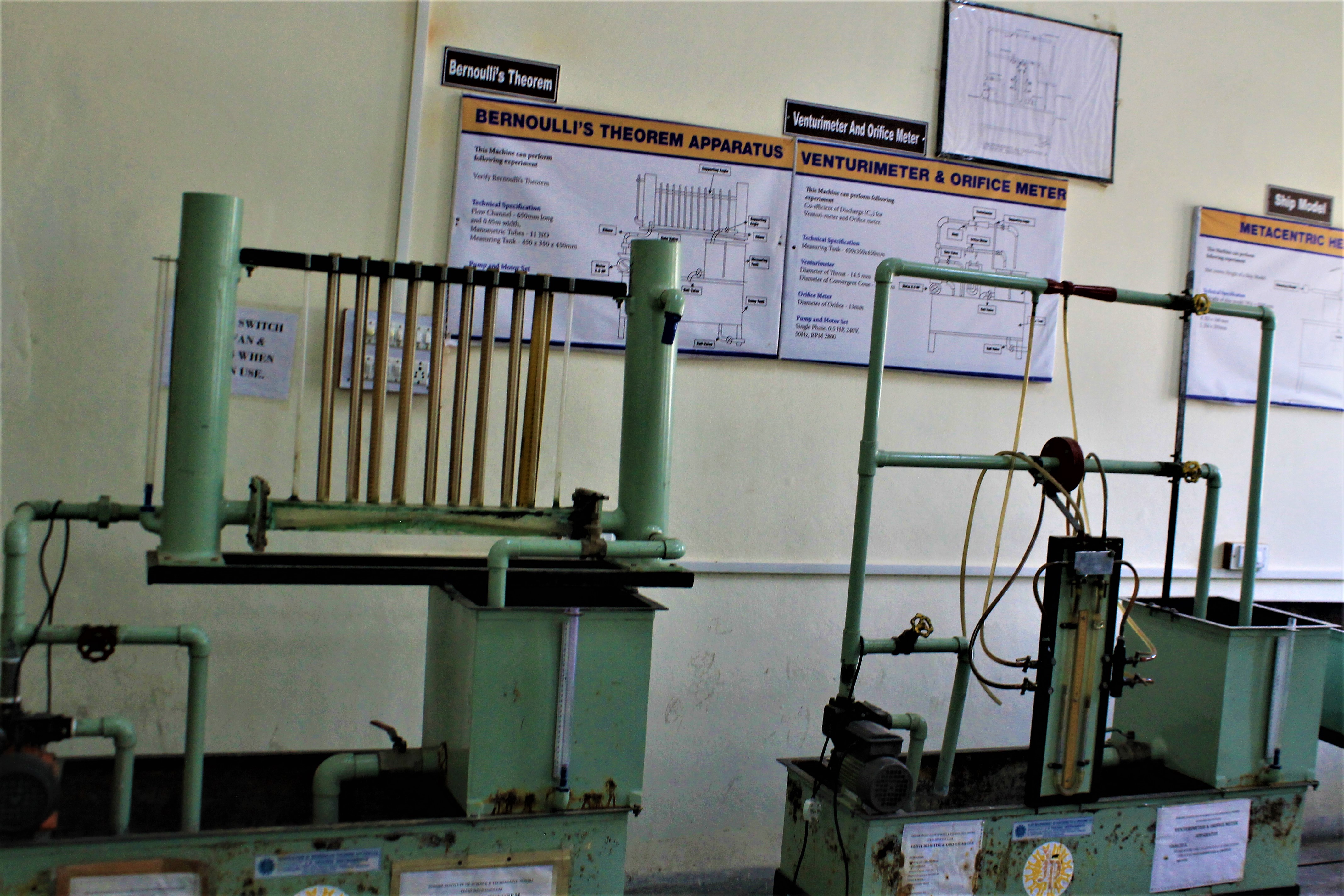

| ME404 | FLUID MECHANICS | To understand the Newton’s law of viscosity and able to explain the mechanics of fluids at rest and in motion by observing the fluid phenomena. |

| Compute force of buoyancy on a partially or fully submerged body and able to analyze the stability of a floating body. | ||

| To understand Euler’s Equation of motion and Deduce Bernoulli’s equation. | ||

| To find energy losses in pipe transitions and to draw energy gradient lines. | ||

| Evaluate pressure drop in pipe flow using Hagen-Poiseuille’s equation for laminar flow in a pipe and distinguish the types of flows and Determine sonic velocity in a fluid. | ||

| ME405 | MANUFACTURING TECHNOLOGY | Upon completion of this course, the students will be able to understand and compare the functions and applications of different metal cutting tools |

| Understand the basic concepts of gear machining | ||

| Understand the basic concepts of plastics and molding method | ||

| Understand the basic concepts of NTM | ||

| The student will be able to write the programming to control and operate NC machines | ||

| ME406 | SOFTWARE LAB | To introduce different drawing softwares to students. |

| To learn about Surface modelling its design & implemntation in engineering applications. | ||

| To know about current developments in CAD. | ||

| To learn about Solid modeling & its applications. | ||

| To know about strategic plan of CAD system design. | ||

| ME407 | 90 hrs Internship based on using various software’s –Internship -II | Exposure to Organizational skills and professional practices. |

| Efficiently completing tasks, fostering good relationship with seniors and subordinates | ||

| Improved Communication & interpersonal skills. | ||

| Exposure to latest technology applications to the specific discipline. | ||

| Identification of relevant problems in the industry and innovative solutions. | ||

| ME 501 | Internal Combustion Engines | To understand different types, parts and working of IC Engines. |

| To learn in details the combustion process in Petrol Engines. | ||

| To learn in details the combustion process in DieselEngines. | ||

| To learn about different types of fuels and their properties used in IC Engines. | ||

| To know about the concepts of Supercarging & Turbocharging of IC Engines | ||

| ME502 | Mechanical Vibrations | Understand the causes and effects of vibration in mechanical systems. |

| Develop schematic models for physical systems and formulate governing equations of motion. | ||

| Understand the role of damping, stiffness and inertia in mechanical systems | ||

| Analyze rotating and reciprocating systems and compute critical speeds. | ||

| Analyze and design machine supporting structures, vibration isolators and absorbers. | ||

| ME503(B) | Dynamics of Machines | To design and analyze the fundamental knowledge of dynamics of machines so that student can appreciate solve problems of dynamic force balance and transmissibility of forces. |

| To calculate the balancing mass with analytical and graphical methods for rotary and reciprocating masses. | ||

| To develop understanding of governor mechanism and its significance on engineering design. | ||

| To develop understanding of dynamic balancing, flywheel analysis, gyroscopic forces and moments. | ||

| To Draw Turning moment diagram for different internal combustion engine and able to design | ||

| ME504 (A) | Industrial Engineering & Ergonomics | Able to use the Charts to record the activities of the people, materials and equipment to find alternative methods which minimize waste and to implement the best method. |

| Able to apply the knowledge to eliminate unproductive activities under the control of the management, supervisor, worker and the design of products and processes | ||

| Able to implement &use the various job evaluation and incentive scheme for the smooth working of the workforce in industry. | ||

| To Apply ergonomic concept to improve working conditions in various industrial environments. | ||

| To estimate information associated with control display systems using information processing theory. Students will be able to evaluate audio, visual and tactile displays. | ||

| ME505 | FEM/CFD | Understand the concepts behind formulation methods in FEM. |

| Identify the application and characteristics of FEA elements | ||

| To develop an understanding for the major theories, approaches and methodologies used in CFD | ||

| Develop element characteristic equation and generation of global equation. | ||

| Able to apply suitable boundary conditions to a global equation for bars, trusses, beams, circular shafts, heat transfer, fluid flow, axi symmetric and dynamic problems and solve them displacements, stress and strains induced. |

||

| ME506 | Python | Basic understanding of python and installation |

| understand the concept of control statement | ||

| Understanding of searching algorithm | ||

| Underatading of sorting algorithm | ||

| Underatading of file handling | ||

| ME507 | Evaluation of Internship II | Demonstrate the application of knowledge and skill sets acquired from the course and workplace in the assigned job function/s |

| Solve real life challenges in the workplace by analysing work environment and conditions, and selecting appropriate skill sets acquired from the course | ||

| Exhibit critical thinking and problem solving skills by analysing underlying issue/s to challenges | ||

| Demonstrate appreciation and respect for diverse groups of professionals by engaging harmoniously with different company stakeholders | ||

| Exhibit professional ethics by displaying positive disposition during internship | ||

| ME508 | Minor Project | Identify a topic in advanced areas of Mechanical Engineering. |

| Review literature to identify gaps and define objectives & scope of the work. | ||

| Generate and implement innovative ideas for social benefit. | ||

| Develop a prototypes/models, experimental set-up and software systems necessary to meet the objectives. | ||

| Analyze the ruslts and evaluate the performance. | ||

| ME601 | THERMAL ENGINEERING AND GAS DYNAMICS | To understand the working of high pressure boiler. |

| To understand the vapour power cycles applied on thermal power plant. | ||

| To understand the concepts of gas dynamics. | ||

| To understand the working of reciprocating air compressor. | ||

| Analyze the flow through varing area ducts with friction and heat transfer. | ||

| ME602 | MACHINE COMPONENT DESIGN | Able to explain the theory behind the different phases of design process. |

| Apply knowledge to design basic elements shaft, keys and couplings. | ||

| Apply knowledge to design springs and power screws. | ||

| Design clutches and brakes depending on need. | ||

| Design and analyze rolling contact or journal bearing. | ||

| ME603(A) | DEPARTMENT ELECTIVE (Turbo-Machinery) | Apply thermodynamic concepts to analyze turbo machines |

| Analyze impulse and reaction steam turbo machines for energy transfer. | ||

| Analyze hydro turbo machines for energy transfer. | ||

| Analyze different types of fans, blowers and compressors for energy transfer. | ||

| General theory and working of different power transmitting turbo machines. | ||

| ME604(C) | OPEN ELECTIVE (Renewable Energy Technology) | To explain in detail about solar energy & its utilization. |

| To explain in detail about wind energy & its utilization. | ||

| To learn about production and application of Biomass. | ||

| To understand different types, parts and working of Hydro Power Systems. | ||

| To explain in detail about geo thermal energy & its utilization. | ||

| ME605 | CAD LAB | Understand geometric transformation techniques in CAD. |

| Develop models to represent curves and surfaces. | ||

| Develop programs to manufacture industrial components | ||

| Devlopment of 3d part nd part | ||

| Simulation study | ||

| ME606 | RDBMS | To learn about normalization and its different forms. |

| To learn about query processing & optimization technique. | ||

| To understand the usage of backup recovery feature of database. | ||

| Study and usage of object or object oriented relational database management software (Oracle). | ||

| Creating and use web database in PHP | ||

| ME607 | INTERNSHIP III | Exposure to Organizational skills and professional practices. |

| Efficiently completing tasks, fostering good relationship with seniors and subordinates | ||

| Improved Communication & interpersonal skills. | ||

| Exposure to latest technology applications to the specific discipline. | ||

| Identification of relevant problems in the industry and innovative solutions. | ||

| ME608 | MINOR PROJECT II | Identify problem in area of Mechanical Engineering which requires further investigation. |

| Identify the methods and materials required for the project work. | ||

| Manage the work with team members. | ||

| Formulate and implement innovative ideas for social and environmental benefits. | ||

| Analyze the results to come out with solutions related to the project work. | ||

| ME701 | Heat and Mass Transfer | Know about the basic concept of heat transfer and its modes. Mechanism of Steady State Conduction. |

| Learn about the Transient Heat Conduction and its applications. | ||

| Learn about Convective Heat Transfer. | ||

| Understand the working principle and types of heat exchangers. And learn about Boiling & Condensation. | ||

| Understand the concept of Radiative Heat Transfer, mass transfer. | ||

| ME702 D | DEPARTMENTAL ELECTIVE Advance Machine Design | Understand the concept of belt, chain and rope drive and their design process |

| Able to design spur and helical gears. | ||

| Able to design of bevel gears. | ||

| Able to design I C engine components such as pystion, cylinder and connecting rod | ||

| Able to design componets like joints, couplings, pressure vessels and power screw. | ||

| ME703A | OPEN ELECTIVE Operation Research and Supply Chain | Formulate and solve linear programming problems |

| Determine optimum solution to transportation problem | ||

| Determine average queue length and waiting times of queuing models. | ||

| Determine optimum inventory and cost in inventory models. | ||

| Understand the decision phases and apply competitive & supply chain strategies | ||

| ME704 | CAD/CAM/CIM | Students will be able to produce CAD drawings which communicate the appropriate manufacturing details, standards, and specifications |

| Students will be able to generate NC code using G-codes & M-codes to machine parts to specifications. |

||

| Students will be able to set-up, program, and operate CNC milling and turning equipment |

||

| Students will be able to Design Flexible manufacturing cell after carrying out Group technology study and finally creating FMS. | ||

| Students will be able to apply knowledge about Computer Aided Quality control and Process Planning Control. | ||

| ME705 | MATLAB and R Programming | To introduce MATLAB & R. |

| Download & Installation of MATLAB & R. | ||

| In detail explanation of various MATLAB commands and functions. | ||

| In detail explanation of various R commands and functions. | ||

| Examples & Case Studies on MATLAB & R Programming. | ||

| ME706 | Major Project-I | Identify problem in area of Mechanical Engineering which requires further investigation. |

| Identify the methods and materials required for the project work. | ||

| Manage the work with team members. | ||

| Formulate and implement innovative ideas for social and environmental benefits. | ||

| Analyze the results to come out with solutions related to the project work. | ||

| ME607 | Evaluation of Internship -III | Demonstrate the application of knowledge and skill sets acquired from the course and workplace in the assigned job function/s |

| Solve real life challenges in the workplace by analysing work environment and conditions, and selecting appropriate skill sets acquired from the course | ||

| Exhibit critical thinking and problem solving skills by analysing underlying issue/s to challenges | ||

| Demonstrate appreciation and respect for diverse groups of professionals by engaging harmoniously with different company stakeholders | ||

| Exhibit professional ethics by displaying positive disposition during internship | ||

| ME801 | REFRIGERATION AND AIR CONDITIONING | Illustrate the fundamental principles and applications of refrigeration and air conditioning system |

| Obtain cooling capacity and coefficient of performance by conducting test on vapour compression refrigeration systems and ice plant | ||

| Present the properties, applications and environmental issues of different refrigerants | ||

| Calculate cooling load for air conditioning systems used for various conditions | ||

| Operate and analyze the refrigeration and air conditioning systems. | ||

| ME802A | DEPARTMENTAL ELECTIVE (AUTOMOBILE ENGINEERING) | Explain in detail about Chassis systems of an Automobile. |

| Explain in detail about steeringsystems of an Automobile. | ||

| Explain in detail about transmission systems of an Automobile. | ||

| Explain in detail about suspension systems of an Automobile. | ||

| Explain in detail about Electrical, control systems and emission standards of an Automobile. | ||

| ME803C | OPEN ELECTIVE (ENTREPRENEURSHIP & MANAGEMENT CONCEPTS) | To learn about different system concepts. |

| To learn about different management concepts. | ||

| To learn about different marketing concepts. | ||

| To know about basics of productivity & operations. | ||

| To explain in detail Entrepreneurship. | ||

| ME804 | SIMULATION & MODELING LAB | To understand the concepts of modelling. |

| To understand the concepts of simulation. | ||

| To model mechanical components using CATIA. | ||

| To model mechanical components using ANSYS. | ||

| To analyze modelled component using ANSYS. | ||

| ME805 | MAJOR PROJECT II | Identify methods and materials to carry out experiments/develop code. |

| Reorganize the procedures with a concern for society, environment and ethics. | ||

| Analyze and discuss the results to draw valid conclusions. | ||

| Prepare a report as per recommended format and defend the work. | ||

| Explore the possibility of publishing papers in peer reviewed journals/conference proceedings. | ||

| Name of the Event | Name of Special Interest Group |

| Training on Additive Manufacturing | Additive Manufacturing |

| Training on CNC Milling, Conventional Milling & EDM | Additive Manufacturing |

| Internship on control and actuator simulation for robotics using Proteus software | Mechatronics |

| Name of the S.I.G. | Name of the event under S.I.G. |

| Data Analytics in R | AI & Industrial Data Engineering |

| Hands on workshop on Solid Works for Automotive | Automotive |

| Hands on Internship on CREO Modeling Software | Advanced Computational & Simulation |

| Session 2021-22 | |

| Name of the S.I.G. | Name of the event under S.I.G. |

| Refrigeration & Air Conditioning | FDP on Research Methodology |

| Additive Manufacturing | Certification course on CNC Simulator Milling |

| Advance Computation & Simulation | Workshop on “Beginner to Professional: CATIA” |

| Internship on Modeling and Simulation using MATLAB and Simulink (Module II) | |

| Internship on Modeling and Simulation using MATLAB and Simulink (Module I) | |

| Internship on “3D Design based Fundamental Course Using CREO | |

| Internship on “Complete Beginner to Advanced Course: CREO” | |

| Aeromodelling club | Training on Aerodynamic Analysis of Vehicle using Ansys |

| AI & industrial Data Engg. | Internship on “Python Beginner to Professional” |

| Mechatronics | Training on Design of Experiment |

| Name of the S.I.G. | Name of the event under S.I.G. |

|

Advanced Computation & Simulation

|

A complete beginner to advanced course: CREO |

| Modelling in AUTOCAD | |

| Additive Manufacturing | Training Course on CNC Simulator Milling |

| Mechatronics | Workshop on Robotic Process Automation |

| Refrigeration & AC | Workshop on HVAC |

| Name of the S.I.G. | Name of the event under S.I.G. |

| Mechatronics | Internship on Python Beginner to Professional |

|

Automotive

|

Training programme on AUTOCAD |

| FDP on Engine Assembly | |

| Additive Manufacturing | Workshop on Welding Technology |

| Name of the S.I.G. | Name of the event under S.I.G. |

|

Advanced Computation & Simulation

|

A complete beginner to advanced course: CREO |

| Internship on 3D Design based Fundamental Course using CREO | |

| Additive Manufacturing | FDP on 3d Printing |

A Special Interest Group (SIG) constitutes a collective within an institution, united by a common passion for advancing a designated sector of mechanical knowledge, learning, or technology. Here, mechanical students collaborate to influence or create solutions pertinent to their SIG group’s specialized field. We offer a platform aimed at enriching students’ understanding of Mechanical Engineering disciplines through active participation in mechanical projects. Currently, the Mechanical Department boasts SIX SIGs and ONE club, each dedicated to fostering excellence within the field.

The Advanced Computational Simulation SIG at our college provides a dynamic platform for students keen on delving into the intricate world of mechanical engineering design software. Through hands-on training and immersive workshops, students within this SIG gain invaluable expertise in various cutting-edge computational tools and simulation techniques. This specialized group fosters a collaborative environment where aspiring engineers explore the depths of structural analysis, fluid dynamics, and thermal simulations. Equipped with state-of-the-art software, participants engage in real-world simulations, honing their problem-solving skills and pushing the boundaries of innovation. Under the guidance of experienced faculty and industry experts, students not only acquire technical proficiency but also develop critical thinking and analytical abilities essential for success in the ever-evolving field of mechanical engineering.

SIG Mentor

| S.No. | SIG/Club Name | Mentor |

| 1 | Advanced Computation & Simulation | Mr. Lokesh Aurangabadkar |

| 2 | Automotive | Mr. Akashdeep Gupta |

| 3 | Additive Manufacturing | Mr. Navdeep Jain |

| 4 | Mechatronics | Mr. Rahul Malviya |

| 5 | AI & Data Engineering | Ms. Neha Yadav |

| 6 | Refrigeration & Air conditioning | Mr. Devkant Varde |

| 7 | Aeromodelling Club | Mr. Suveer Dubey |

| 8 | SAE Club | Mr. Ashish Khare |

2. Additive Manufacturing

The Additive Manufacturing SIG at our college offers a unique opportunity for students to delve into the fascinating realm of cutting-edge 3D printing and Scanner technology. With access to state-of-the-art and government-funded 3D printers, participants receive comprehensive training in design, modeling, and fabrication processes. This SIG empowers students to explore innovative avenues in product development, leveraging the limitless potential of additive manufacturing. Through hands-on experience and mentorship from industry professionals, students gain invaluable insights into the intricacies of additive manufacturing techniques, enabling them to bring their creative ideas to life. By fostering a collaborative environment and encouraging experimentation, the Additive Manufacturing SIG equips students with the skills and expertise needed to thrive in the rapidly evolving landscape of modern engineering and design.

SIG Mentor- Mr Vipin Patel

3. AI & Industrial Data Engineering (AIDE)

The AI & Industrial Data Engineering SIG at our college provides students with a comprehensive training program focused on artificial intelligence (AI) and data science applications within the realm of mechanical engineering and automation industries. Participants delve into the intricacies of AI, machine learning algorithms, and data analysis techniques tailored specifically to address challenges in mechanical and automation sectors. Through hands-on workshops and tutorials, students gain proficiency in programming languages such as Python and MATLAB, essential for implementing AI solutions and data analytics. Additionally, they explore advanced AI modeling tools like Weka, enabling them to develop sophisticated models for real-world applications. This SIG fosters a collaborative environment where students harness the power of AI and data engineering to drive innovation and solve complex problems in mechanical and automation domains.

SIG Mentor- Dr Dheerendra Vikram Singh

4. Automotive

The Automotive SIG at our college offers students an immersive training experience in the design, modeling, and simulation of all-terrain vehicles (ATVs) and electric kart vehicles. Through hands-on workshops and projects, students learn to fabricate both ATV and e-kart every year, gaining practical insights into vehicle engineering. Moreover, participants actively engage in national and international racing competitions, showcasing their expertise and pushing the boundaries of automotive innovation. Utilizing a diverse array of modeling and simulation software including AutoCAD, SolidWorks, CATIA V5, Adams, and Ansys, students analyse vehicle performance and optimize design parameters. Notably, students have clinched victories in national racing competitions, a testament to their exceptional design prowess and dedication to automotive excellence.

SIG Mentor- Mr Aakashdeep Gupta

5. Refrigeration and Air Conditioning

The Refrigeration and Air Conditioning SIG at our college provides students with invaluable practical exposure to a wide range of refrigeration and air conditioning systems along with their components. Through hands-on training sessions and workshops, participants delve into the intricacies of designing, installing, and maintaining these systems, gaining comprehensive insights into their operation. Additionally, students receive training in various software applications pertinent to the field of Refrigeration and Air Conditioning (RAC), enhancing their proficiency in system analysis, design, and troubleshooting. This SIG serves as a platform for students to develop both theoretical knowledge and practical skills essential for successful careers in the RAC industry, ensuring they are well-equipped to tackle real-world challenges in this specialized field.

SIG Mentor- Mr Lokesh Aurangabadkar

The Mechatronics SIG at our college offers students an enriching training experience encompassing software and tools crucial for mechatronics, automation, and robotics. Through interactive workshops and practical projects, participants gain proficiency in a variety of software applications tailored to these interdisciplinary fields. From CAD software for designing mechanical components to PLC programming tools for automation, students delve into a diverse array of tools used in mechatronic systems. Moreover, they explore programming languages and simulation environments specific to robotics, honing their skills for developing and controlling robotic systems. The Mechatronics SIG provides a collaborative platform where students merge mechanical, electrical, and computer engineering principles, preparing them for impactful contributions in the realms of automation and robotics.

SIG Mentor- Mr Suveer Dubey

It is an initiative of Ministry of Human Resource Development (MHRD) under the National Mission on Education through ICT. The Department of Mechanical Engineering conducts virtual labs programs organized by different IITs across the country

SWAYAM is an initiative by Ministry of Human Resource Development, Government of India. World’s largest SWAYAM MOOCs (Massive Open Online Courses), a new paradigm of education for anyone, anywhere, anytime, as per your convenience, aimed to provide digital education free of cost and to facilitate hosting of all the interactive courses prepared by the best more than 1000 specially chosen faculty and teachers in the country. SWAYAM MOOCs enhances active learning for improving lifelong learning skills by providing easy access to global resources.

There are a number of career opportunities available in the mechanical engineering sector. These opportunities are exponentially increasing day by day with new emerging trend. Mechanical engineering graduates are sought by employers in almost all sectors of the engineering industry. These include:

(A) Patents

(B) Book Publications

( C ) Research Supervision

| S.No. | Name of

Research Supervisor |

Research Program | Scholar Name | Enrolment University of Scholar | Scholar Enrolment Year | Status of PhD |

| 1 | Dr D V Singh | PhD | Mr Bhavesh Devra | Amity, Japiur | 2018 | Thesis Writing |

| 2 | Dr D V Singh | PhD | Mr Avinash Yadav | LPU,Jalandhar | 2019 | Coursework is completed |

| 3 | Dr.Vivek Mishra | PhD | Mr. B. Laxman Rao | CSVTU, Chhattisgarh | 2019 | Coursework completed and Registration |

(D) Faculty Research Persuasion-PhD

| Sr.No. | Name of Faculty Member | Research Program | Enrolment in University | Enrolment Year | Status of PhD |

| 1 | Mr Lokesh Aurangabdkar | PhD | DAVV,Indore | 2018 | RDC Cleared |

| 2 | Mr Punit Mishra | PhD | DAVV,Indore | 2017 | RDC Cleared |

| 3 | Mr Mukesh Sharma | PhD | DAVV,Indore | 2018 | RDC Cleared |

| 4 | Mr. Suveer Dubey | PhD | Manipal University Jaipur | 2021 | Enrolled |

(F) Research Publications-International Journal

(G ) Research Publications-International Conference/Seminar/Symposia

1 D.V.Singh and T.N.Verma.“Simulink simulation for predicting thermodynamic properties of water –lithium bromide solution using ANN”. International Conference on Soft Computing Theories and Applications,held at National Institute of Technology Patna, Patna, India on 27 – 29 Dec 2019.

11 .N. K. Gandhi,A. K. Dwivedi, C.Chopra and A. Singh, “Investigation on Surface Hardening of Mild Steel by Carburizing Diffusion Process”. 14th International Conference on Global Advancement In Engineering, Management, Pharmacy, Science And Humanities, held at Mathura Devi Group of Institutions, Indore, 19-20 Jan 2019.

12 .N. K. Gandhi, P. Kumar, P. Rathore, P. Shinde and M. Sharma,“Design Of Sustainable Geothermal Air Conditioner”. 14th International Conference on Global Advancement In Engineering, Management, Pharmacy, Science And Humanities, held at Mathura Devi Group of Institutions, Indore, 19-20 Jan 2019.